The case of the factory for the production of artificial flooring "FFU Production"

The case of the factory for the production of artificial flooring "FFU Production"

The case concerning the FFU Production artificial turf plant is an attempt to accuse the Ukrainian Football Association of being involved in... modernizing the country's football infrastructure. But the lack of common sense in the accusations against the UAF does not allow the materials to be submitted to the court.

The case of the plant for the production of artificial turf "FFU Production"

The case concerning the "FFU Production" artificial turf plant is an attempt to accuse the Ukrainian Association of Football of being involved in... modernizing the country's football infrastructure. But the lack of common sense in the accusations against the UAF does not allow the materials to be submitted to the court.

The need to create a factory with production of artificial covering

The construction of the plant in Ukraine was determined by the need to develop the country's sports infrastructure. We are talking about football centers, playgrounds and full-sized fields, etc.

Prior to that, uniform construction technologies and quality standards for fields with an artificial surface were not used in Ukraine. And if such construction was carried out, then cheap and low-quality materials were used, which negatively affected the safety and longevity of the operation of the sites.

The Ukrainian Football Association (UAF) developed a strategy for the development of sports infrastructure and initiated the creation of a factory for the production of artificial turf.

In 2016, the strategy was approved and approved first by the UAF Executive Committee, and then by the UAF Congress.

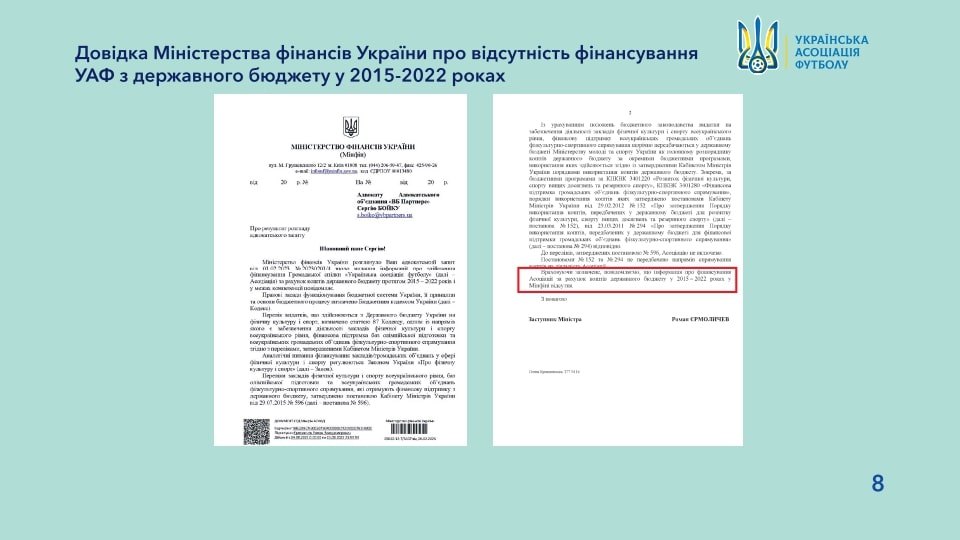

During the construction of the plant, not a single budget hryvnia was used, it was built with the funds of the Ukrainian Football Association, and therefore 100% belongs to Ukrainian football.

The need to create a plant for the production of artificial turf

The construction of the plant in Ukraine was determined by the need to develop the country's sports infrastructure. We are talking about football centers, playgrounds and full-sized fields, etc.

Prior to that, uniform construction technologies and quality standards for fields with an artificial surface were not used in Ukraine. And if such construction was carried out, then cheap and low-quality materials were used, which negatively affected the safety and longevity of the operation of the sites.

The Ukrainian Association Football (UAF) developed a strategy for the development of sports infrastructure and initiated the creation of a plant for the production of artificial turf.

In 2016, the strategy was approved and approved first by the UAF Executive Committee, and then by the UAF Congress.

During the construction of the plant, not a single hryvnia budget was used, it was built with the funds of the Ukrainian Association of Football, and therefore 100% belongs to Ukrainian football.

Involvement of an intermediary company S.D.T. (UAE)

Construction of a plant for the production of artificial grass is a complex technological process. In particular, it includes the purchase of high-tech equipment from suppliers from different countries on several continents.

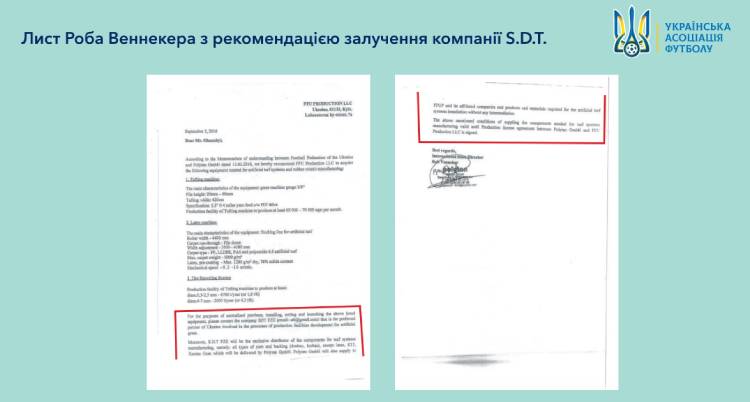

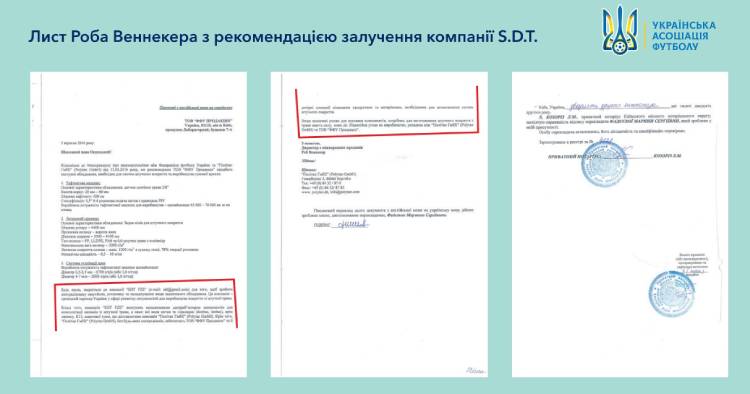

To coordinate all these processes, the UAF engaged the SDT engineering company from the United Arab Emirates. Such a choice is the recommendation of a representative of the world-famous German manufacturer of artificial grass Polytan. This is confirmed by an official letter from a representative of a German company.

Involvement of intermediary company SDT (UAE)

Construction of a plant for the production of artificial grass is a complex technological process. In particular, it includes the purchase of high-tech equipment from suppliers from different countries on several continents.

To coordinate all these processes, the UAF engaged the engineering company SDT from the United Arab Emirates. Such a choice is the recommendation of a representative of the world-famous German manufacturer of artificial grass Polytan. This is confirmed by an official letter from a representative of a German company.

The quality of the coating from Polytan recognized by FIFA and UEFA

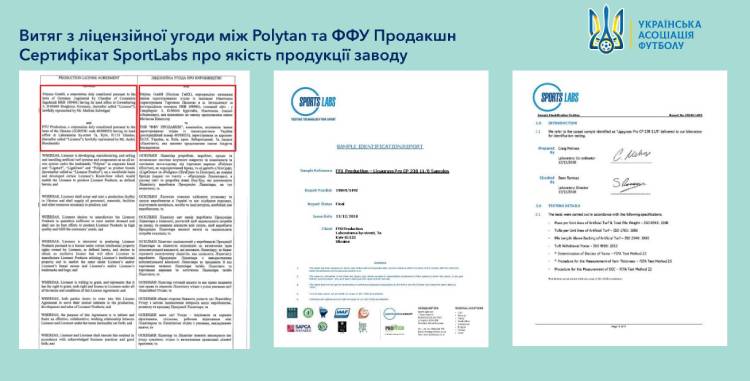

The "FFU Production" plant produces artificial covering for fields using Polytan technology. The company issued the relevant certificate to the FFU Production plant.

The artificial coating of this manufacturer has many advantages: ultra-strong fiber, wear resistance and durability; environmental friendliness; hypoallergenicity; greater volume and density of pile.

The quality of the coating is also confirmed by the studies of SportLabs, an internationally accredited company.

In addition, the company Polytan is the supplier of the covering for the fields built in Switzerland near the headquarters of FIFA and UEFA.

The quality of the covering from Polytan was recognized by FIFA and UEFA

The "FFU Production" plant produces artificial covering for fields using Polytan technology. The company issued the relevant certificate to the "FFU Production" plant.

The artificial turf of this manufacturer has many advantages: ultra-strong fiber, wear resistance and durability; environmental friendliness; hypoallergenicity; greater volume and density of pile.

The quality of the turf is also confirmed by the studies of SportLabs, an internationally accredited company.

In addition, the company Polytan is the supplier of the covering for the fields built in Switzerland near the headquarters of FIFA and UEFA.

The rest of the listed S.D.T. there were funds aimed at repaying the obligations of the UAF

After finalizing all processes, SDT was to return the remaining funds to the plant. This money is the difference between the planned and actual costs, which was saved by choosing a more favorable offer from the contractor for setting up the equipment.

The association decided to use the overpayment for its targeted needs — repayment of obligations to the famous Italian referee Pierluigi Collina, who signed a long-term contract with the previous management of the association (then still FFU) and served as the curator of the referee corps of Ukraine. The previous management owed the Italian a certain amount. Negotiations were held with him and this payment was made within the framework of the settlement agreement reached.

The association provided the investigation with documents on the transfer of funds to Collina (payment orders, statements, contracts). However, the investigation hides them.

The balance of the listed SDT funds were directed to repaying the obligations of the UAF

After finalizing all the processes of SDT had to return the rest of the funds to the plant. This money is the difference between the planned and actual costs, which was saved by choosing a more favorable offer from the contractor for setting up the equipment.

The association decided to use the overpayment for its targeted needs — repayment of obligations to the famous Italian referee Pierluigi Collina, who signed a long-term contract with the previous management of the association (then FFU) and served as the curator of the referee corps of Ukraine. The previous management owed the Italian a certain amount. Negotiations were held with him and this payment was made within the framework of the settlement agreement reached.

The association provided the investigation with documents on the transfer of funds to Collina (payment orders, statements, contracts). However, the investigation hides them.

Non-involvement in the crime was established by NABU

The National Anti-Corruption Bureau of Ukraine (NABU) investigated the case of the construction of the plant for four years: dozens of interrogations, searches, international cooperation with foreign jurisdictions (Denmark, Estonia, Germany, UAE, USA) were conducted.

On the basis of the collected evidence, it was established that the president of the UAF and the general secretary of the association were not involved in the crime. The decision to this effect was issued by the Office of the General Prosecutor of Ukraine.

In addition, the investigation did not prove the fact of the damage caused.

Within a year, despite the lack of new evidence, the National Police, where the case was transferred, again charged the president and general secretary of the UAF.

Non-involvement in the crime was established by NABU

The National Anti-Corruption Bureau of Ukraine (NABU) investigated the case of the construction of the plant for four years: dozens of interrogations, searches, international cooperation with foreign jurisdictions (Denmark, Estonia, Germany, UAE, USA) were conducted.

On the basis of the collected evidence, it was established that the UAF President and the General Secretary of the association were not involved in the crime. The decision to this effect was issued by the Office of the General Prosecutor of Ukraine.

In addition, the investigation did not prove the fact of the damage caused.

Within a year, despite the lack of new evidence, the National Police, where the case was transferred, again charged the President and General Secretary of the UAF.

Participation of the FFU Production plant in the construction of sites

The FFU Production plant was not a monopoly in receiving budget orders. In particular, the purchase of the coating was carried out by the decision of the construction customer in the regions of Ukraine not only from the FFU Production plant, but also from various manufacturers from Europe and Asia.

As for the construction of playgrounds, the company "FFU Production" directly acted as a contractor for the construction of only 66 playgrounds in the city of Kyiv (this is only 8% of the total number of fields under the program).

Participation of the "FFU Production" plant in the construction of playgrounds

The "FFU Production" plant was not a monopoly in receiving budget orders. In particular, the purchase of the turf was carried out by the decision of the construction customer in the regions of Ukraine not only from the "FFU Production" plant, but also from various manufacturers from Europe and Asia.

As for the construction of playgrounds, the company "FFU Production" directly acted as a contractor for the construction of only 66 playgrounds in the city of Kyiv (this is only 8% of the total number of fields under the program).

FIELDS BUILT BY "FFU PRODUCTION" IN THE CAPITAL

PLAYGROUNDS BUILT BY “FFU PRODUCTION” IN THE CAPITAL